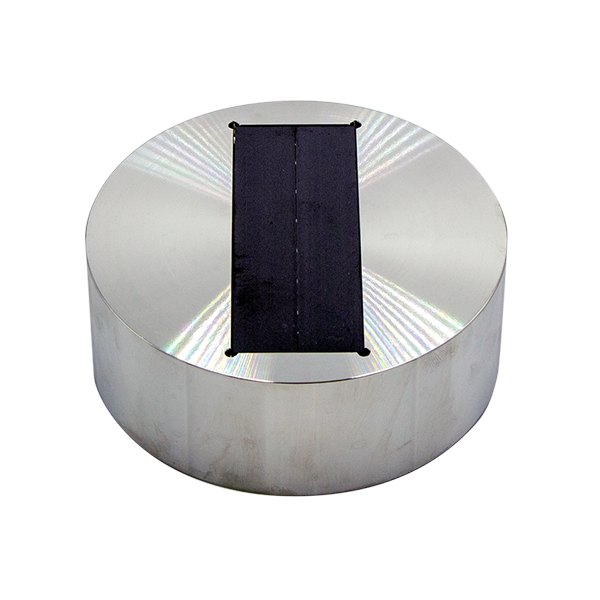

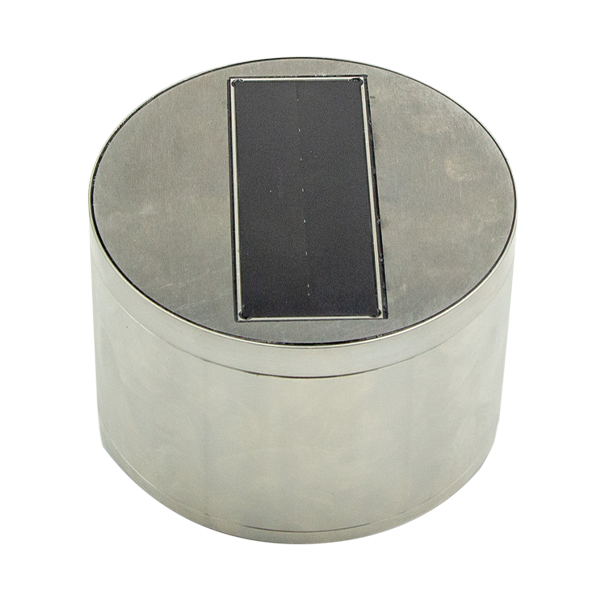

The hardest mixer probe for use in pan mixers, ring trough mixers, planetary and twin-shaft mixers. The replaceable probe head is made of steel and a solid hard metal plate with a rectangular window made of a special ceramic.

Fresh Concrete Online

| Temperature range | 0°C … +70°C |

| Power supply | +12V to +24V DC, approx. 3W |

| Besondere Bedingungen- | – |

| Signal output | 2 x analogue output 0(4)...20mA Output 1: Humidity in % Output 2: Temperature or optionally conductivity or standard deviation |

| Interfaces | RS485 or IMP bus |

| Sensor dimension | Ø108 mm x 135 mm (without plug) |

| Weight | 3,70 kg |

| IP protection class | IP67 |

Constructive variants

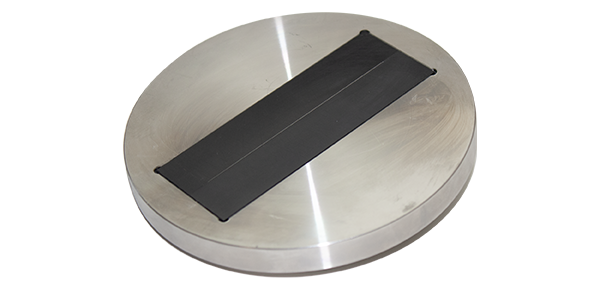

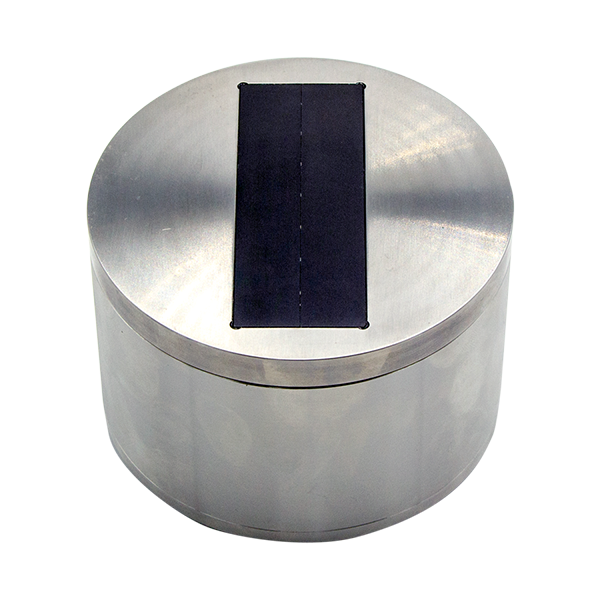

Round sensor, medium (carbide)

Rectangular sensor (normal)

- Disc mixer

- Ring trough mixer

- Intensive mixer

- Single or twin-shaft mixers

- Countercurrent mixer

- Planetary mixer

- Ribbon blender

- Conveyor belt

- Screw conveyor

Accessories

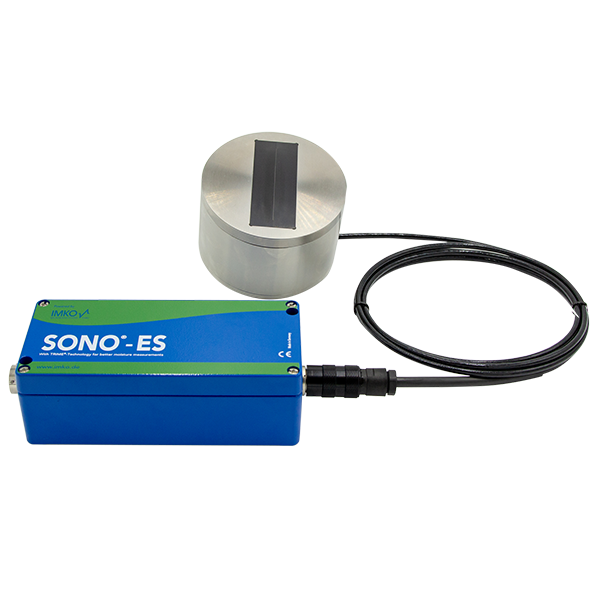

Stand-alone display and configuration for reliable process control with SONO or TRIME humidity probes. Up to 4 SONO probes can be connected online via a serial interface. For displaying measurement data, setting the operating mode and other functions.

USB to RS485 and IMP bus converter module. For connecting SONO probes to a PC under Windows via the serial interface. For creating your own calibrations, test measurements with measurement data storage and other functions.

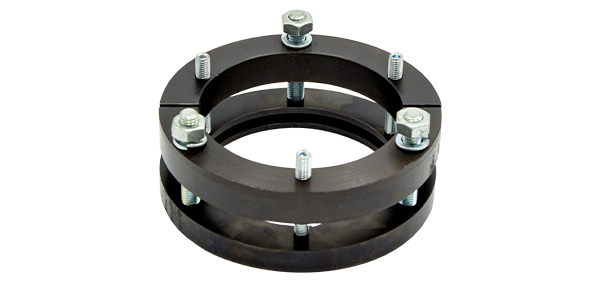

Weld-on flange 108mm for SONO MIX for mixer mounting.

SONO sensor cable 4m; 6 twisted pair cables, 6 x 2 x 0.25mm2, shielded; 10pin MIL connector

SONO sensor cable 10m; 6 twisted pair cables, 6 x 2 x 0.25mm2, shielded; 10pin MIL connector

SONO sensor cable 25m; 6 twisted pair cables, 6 x 2 x 0.25mm2, shielded; 10pin MIL connector

SONO fixed cable gland, 5m sensor cable, 6 twisted pair cables, 6 x 2 x 0.25mm2 , shielded; IP 67

Replacement wear head for SONO VARIO Xtrem Ø 108mm

Alternative sensor

MOISTURE MEASUREMENT CONSTRUCTION

SONO VARIO HC

Art. -Nr. 308075

MOISTURE MEASUREMENT CONSTRUCTION

SONO VARIO Xtrem HC Carbid

Art. -Nr. 308103

MOISTURE MEASUREMENT CONSTRUCTION

SONO VARIO Xtrem HC V4A

Art. -Nr. 308102

MOISTURE MEASUREMENT CONSTRUCTION

SONO MIX Mini HC

Art. -Nr. 308094

MOISTURE MEASUREMENT CONSTRUCTION

SONO SILO Xtrem HC

Art. -Nr. 308077

MOISTURE MEASUREMENT CONSTRUCTION

SONO ES MIX Mini HC

Art. -Nr. 998241

MOISTURE MEASUREMENT CONSTRUCTION

SONO EX MIX Mini HC

Art. -Nr. 998242